IMSeco designed and manufactured a range of “SCRT” (SCR+DPF) systems which was shipped to the UK in the UK during the first quarter of 2019 for compliance with DEFRA’s MCPD (Medium Combustion Plant Directive) which was transposed into UK Law as from January 2018.

The new directive sets emissions limits for NOx of 190mg/Nm3 (15% O2) for Diesel Powered Generation Equipment with thermal ratings between 1 and 50MWth which are being introduced dependent on engine size between Jan 2019 and Dec 2029.

Although not required under the directive, the client decided to include “Diesel Particulate Filters (DPF)” within the design to “Future-Proof” any potential future legislation.

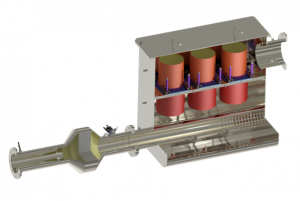

The first “SCRT” system which was for the Volvo Penta TAD532GE (4.76Ltr/129kw) engine incorporated 3 x DPF and 3 x SCR+ASC Modules in a fully stainless-steel reactor.

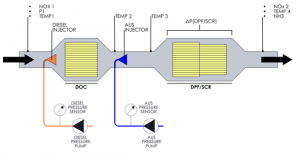

To ensure the DPF is always kept clean, IMSeco incorporated an Active Hydrocarbon (HC) injection system that vaporises tiny droplets of fuel over the DOC (Diesel Oxidation Catalyst).

The SCR (NOx Abatement) system utilises an “Air-Less AdBlue Injector with Pump” that delivers the AdBlue from a small on-board tank. Once injected the AdBlue decomposes into Ammonia and gets dispersed through Mixing Pipe embedded within a lower chamber.

The “Closed Loop” system comes with an array of pressure, temperature and NOx sensors and an Electronic Control Unit that controls the AdBlue Dosing and measure the NOx reductions being achieved in Real Time.

The above illustration shows the 3-module design for the Volvo TAD532GE. For the larger Volvo TAD1342GE. (12.78 Ltr/343kw) engine a total of 6 x DPF and 6 x SCR+ASC modules were used “2 rows of 3) as shown in the photograph below:

A nice feature about the design is that Inlet and Outlet Pipework can be positioned on either side, plus it has a removable lid which allows the substrates to be retracted easily for maintenance.

For more information on this project, or if you have a requirement, please mail us today at sales@silencers.co.uk